What do electrical control system engineers do?

In basic terms, electrical control systems work by measuring an error signal and adjusting the system’s response to achieve the desired outcome.

Cruise control in an automatic car and automatic temperature controls in an office block are both examples of electrical control systems at work.

In an industrial setting, conveyor belts, robotics and automated manufacturing processes are all controlled electronically.

A control systems engineer is responsible for designing, developing, and managing electrical control systems in industrial applications.

But what do they actually do? And what role do they play in helping manufacturing and engineering operators achieve improvement through technology?

Read on to find out.

What does an electrical control systems engineer do?

Control systems engineering is a discipline that uses control theory to design and develop systems that automate mechanical and electrical manufacturing and industrial processes.

When it comes to large-scale manufacturing, there are always improvements to be found and ways to make a process better.

Control systems engineers are highly skilled and qualified professionals who create systems to make automated processes safer, and more efficient and sustainable.

The systems they design use tools such as sensors or detectors to continually monitor the real-time performance and results of an industrial process and feed this information back to a central database.

The data is then analysed to identify trends and changes and predict events such as failure or downtime. The control system responds by changing its outputs to optimise the process to achieve the desired performance.

A control systems engineer is responsible for researching, designing, developing and managing the equipment used to monitor and control industrial processes, systems and machinery. In short, they make sure the processes run safely and efficiently.

To create the most effective solutions, they need in-depth knowledge of the processes they want to optimise and the results or outcomes the operator is looking to achieve. Their roles and responsibilities include:

Related links:Choosing the right COB LED

4-Megapixel USB Cameras vs. 1080p: Unraveling the Differences in Image Quality

SMT PCB Buffer vs. Conveyors: Which Is Better for Your Assembly Line?

Is Flexible Conduit Explosion-Proof?

What are the Advantages of Deep Cycle Battery?

Which diesel generator is best for home?

The Ultimate Guide to Selecting the Perfect Outdoor LED Video Wall

- Understanding and knowledge about the client’s business and requirements

- Developing control solutions that meet customer needs or solve their problems

- Designing and constructing control systems

- Defining control algorithms and selecting the right tools and equipment

- Overseeing the installation of ICT equipment

- Developing hardware and software for control equipment

- Maintaining, expanding or upgrading existing control systems

- Writing, programming or optimising PLC, HMI, Vision and Robotics

- Ensuring the control system meets specification and works safely and efficiently

- Producing training materials and documentation

Training system users, technicians and other engineers - Ongoing maintenance, servicing and troubleshooting once the control system goes live

Ultimately, electrical control system engineers make manufacturing equipment and processes work more safely, predictably and efficiently.

They optimise the performance of manufacturing and engineering processes to improve quality and output, enhance productivity and better predict maintenance and downtime requirements.

Automated control systems are used widely across many industries, including automotive, utility, energy, power, aerospace, healthcare, electronics and ICT.

If a system needs improving to optimise the way it works, it’s usually down to a control system engineer to develop the solution and make it better.

In short, without engineers, manufacturing wouldn’t be possible. Control system engineers bring skills, knowledge and experience to every project they work on to ensure it runs as smoothly as possible.

So, if you’re looking to make your processes smarter, safer and more sustainable, Banelec’s team of specialist electrical control system engineers can make it happen.

How can Banelec help?

Banelec is a world leader in creating electrical control solutions.

We’ve integrated PLCs and robotics into electrical control systems for some of the world’s biggest manufacturing brands.

Our team of highly skilled and qualified engineers brings diverse experience, knowledge and personality to every project we work on to exceed your requirements and specifications.

Our automation services include complete systems, electrical controls, robotics and conveyor controls.

Whatever you do, if you want to do it better, get in touch.

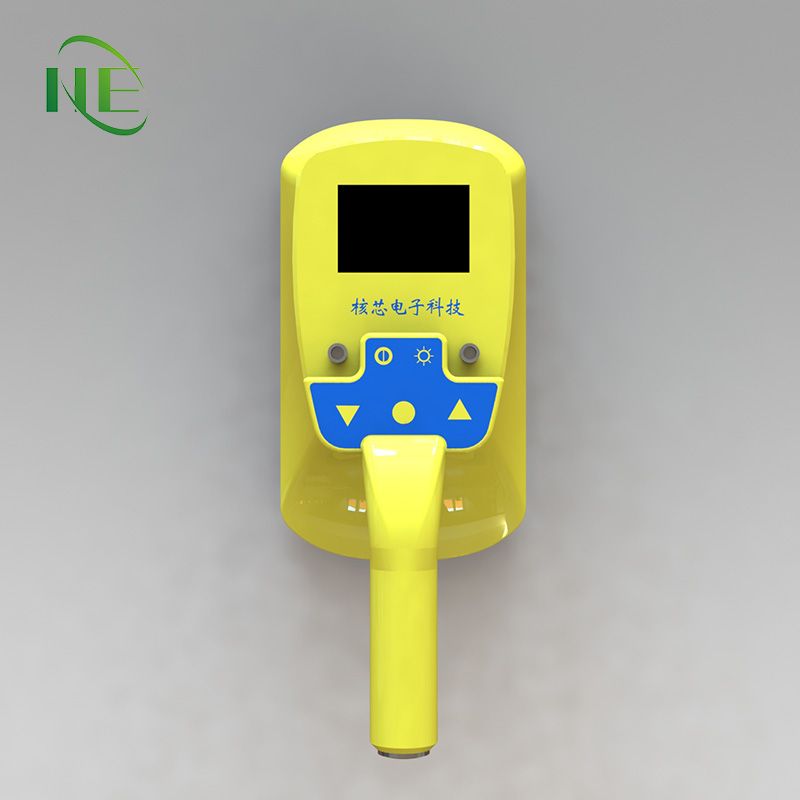

An EV motor controller is a key component in the operation of an EV. It is responsible for controlling the flow of electricity from the EV's battery pack to the electric motor, ensuring that the motor receives the right amount of power at the right time. Electric vehicle (EV) motor controllers are an essential component of any EV. They are responsible for regulating the flow of power from the battery to the electric motor, which in turn drives the wheels of the vehicle. These controllers play a crucial role in determining the performance and efficiency of an EV, as well as its overall range and battery life. https://www.embitel.com/motor-control-solution-for-electric-vehicle-drivetrain

What do electrical control system engineers do?

How does a Motor Controller for Electric Vehicle Work?

Related links:Energy storage 101: how energy storage works

Advantages of Flexible Metal Conduit in Electrical Wiring

What’s the Difference between Start Stop Car Batteries & Normal Batteries?

What Rating Is an Explosion-Proof Light?

What are the pros and cons of glass insulators?

Unveiling the Distinctions: LED Walls vs. Video Walls

What operating systems are supported by Rockchip SOM?